MANUFACTURING

01/Soft Machining - Turning

TURNING

TURNING

01

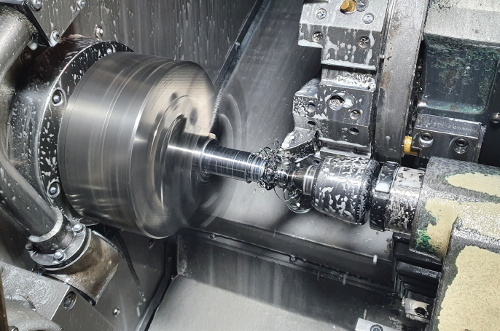

The main purpose of soft machining in FKL is the manufacture of bearing rings, housings, hub shafts, cardan shafts, as well as the processing of cast housings for bearing units.

Incoming material for turning: bars, tubes, forgings, castings, rings.

Machines used for turning are six-spindle lathes for large series and CNC machines for processing rings of larger dimensions and small series. Technological possibilities of soft machining of rings for bearings in FKL:

- multispindle machines: diameters up to 100 mm

- CNC machines: diameters up to 500 mm.

The basic document which defines methods and norms for measuring predefined parameters of processing is the Process Control Plan. It contains:

- dimensional control (inner diameter/outer diameter/ width of rings, angles, raceways, depressions, radius)

- shape deviations (ovality, profile deviation, parallelism, conicity, raceway deviations, clearance)

- visual inspection

- methods and instruments for measuring

- frequency of measurements

02/Heat Treatment

HEAT

TREATMENT

HEAT

TREATMENT

02

Heat treatment is a set of operations for heating, keeping obtained temperature and cooling hard metal alloys in order to achieve the desired properties by changing the internal structure of the metal.

The main technological operations of heat treatment in FKL are:

- hardening

- cementation

- normalization

- induction hardening

- tempering and annealing.

The main goal is to achieve a certain hardness of the bearing rings according to the drawing. The lifetime of bearings directly depends on the hardness of the rings.

03/ Hard Machining - Grinding

GRINDING

GRINDING

03

The main goal of hard machining (grinding) in the production of bearings is to achieve the given geometry and roughness for the rings.

Grinding operations in FKL are following:

- centerless grinding

- straight grinding

- raceway grinding on inner ring

- raceway grinding on outer ring

- bore grinding on inner ring

- inner ring raceway honing

- outer ring raceway honing

According to the process plan for hard machining, the parameters are defined, controlled and recorded similarly to soft machining. It is especially important to emphasize that the process of the first piece approval includes also the laboratory measurement of roughness, circularity, waviness of the raceway

04/Assembly

ASSEMBLY

ASSEMBLY

04

The bearings are assembled on special assembling lines, which include the following operations:

- sorting of rings

- pairing of rings with rolling elements and cage

- 100% measurement of radial or axial clearance

- 100% vibration measurement in three frequency bands

- grease filling and grease control

- bearing closure and closure control

- marking

- packaging

Samples are taken from each series of mounted bearings to check the final quality of the product in accordance with the assembly control plan. The measurement of finished bearings is performed in the laboratory. It is followed by a certificate of compliance with the FKL standard issued for each series.

After packaging, in accordance with a specific work order, the goods are transfered to the finished goods warehouse. The sales department receives the information, makes the shipping documents and delivers the goods to the buyer.