Sealing range overview for standard program

FKL offers economical and space-saving sealing solutions. Bearings can have shields and/or seals at one or both sides. Bearings that are sealed at both sides can be re-lubricating or maintenance-free. Sealed bearings are generally used where sufficiently effective external sealing cannot be provided due to inadequate space or cost effectiveness. Bearings fitted with shields are used where the possibility of impurity ingression is low and there is no danger of water or steam contact with the bearings or where high speed or operating temperature of the bearings is required. Bearings fitter with contact seals are preferred to be used where contamination is moderate and where moisture, water, steam may occur or where a long exploitation life without maintenance is required.

Bearing sealing

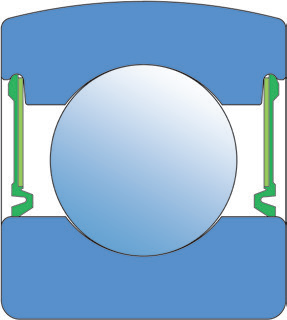

Fig. 1 Sealing 2Z Non-contact sealing with Steel sheet shield of simple and cheap make. Grease prevents penetration of rough impurities. Allows the highest speeds. It is used with the deep groove ball bearings.

Fig. 2 Sealing 2RS The older type of the single seal. Prevents penetration of soil, dust and water and since exposed to the impact of abrasive particles is expendable more than some new types of seals. Due to extended friction, the permitted speeds are lower. It was gradually replaced with the improved versions of (2S). Because of the traditional reasons Y bearings with this kind of seal do not have the additional sealing mark. It is used with the Y-bearings and deep groove ball bearings.

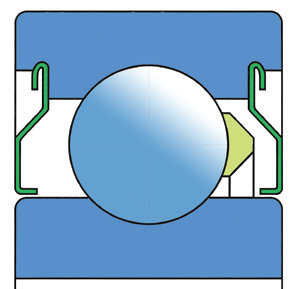

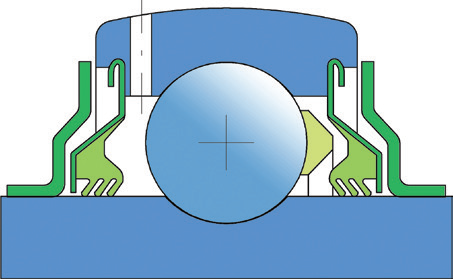

Fig. 3 Sealing 2S Single seal with the labyrinth between the sheet part and the rubber lip which conducts the contact sealing. The friction and speeds are the same as with 2RS but provides much better protection against the rough impurity particles. This is very good sealing system: the sheet part protects the seal from the soil, dust and rough particles. At the same time makes the labyrinth with the rubber part. The rubber part provides contact sealing which prevents penetration of finer impurities, water, moisture, steam etc. Suitable for neutral conditions because of the presence of the foreign materials. It is used with the Y bearing (standard) and deep groove ball bearings.

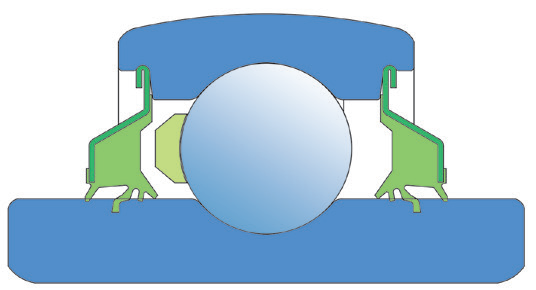

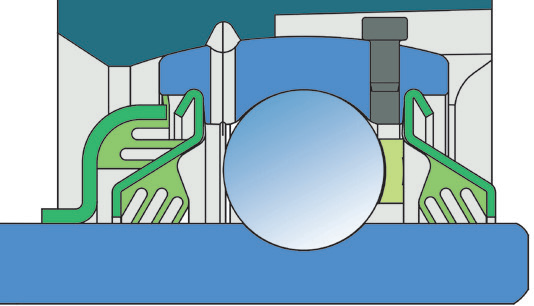

Fig. 4 Sealing 2F Dual sealing, protection cover placed on the inner ring protects against rough impurity particles and makes the labyrinth with the sheet part of the seal; then the sealing 2S type, with the labyrinth between the sheet part and the rubber lip that conducts the contact sealing. The friction and speeds are the same as with 2S but has much better protection against rough impurity particles. It is very good sealing system: the sheet part protects the seal from the soil, dust and rough particles. At the same time makes the labyrinth with the rubber part. The rubber part provides the contact sealing that prevents the penetration of the finer impurities, water, moisture, steam etc. Suitable for heavier conditions due to better protection against foreign matters. It is used with the Y bearings (standard).

Fig. 5 Sealing 2T By construction is the same as 2S, except rubber lip is tripled. Therefore, it seals better but has even larger friction. The permitted speeds are much lower, up to 500 rpm. It emerges out of external ring width and is applied only with special bearings for the agricultural machines (practically standard sealing for the disc harrow bearings) and to the less extent, Y - bearing program (delivery is made according to special request). Additional protection provided by metal-sheet cap is also available (designation 2TC).

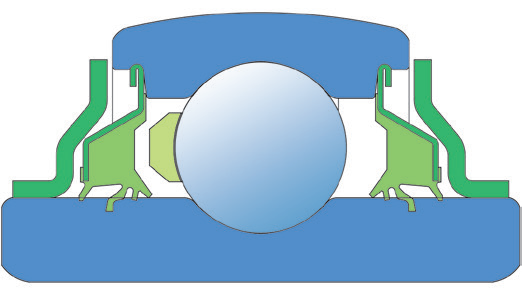

Fig. 6 Sealing 2TB Dual sealing, combination 2T and stronger protection steel. Friction and speeds are the same as 2T, but considerably better protection against rough dirt. This type of sealing is applied in agricultural machinery. Protection steel protects from soil, dust, rough dirt and mechanical impact on the seal. Triple-lips seal performs contact sealing that prevents penetration of finer dirt, water, damp etc. Suitable for difficult working conditions with aggressive presence of foreign matter. Used with Y bearing units 2TB.

Fig. 7 Sealing 2P By construction is the similar as 2T, except rubber lip is fivefold. Therefore, it seals better but has even larger friction. The permitted speeds are much lower, up to 500 rpm. It emerges out of external ring width and is applied only with special bearings for the agricultural machines (practically standard sealing for the disc harrow bearings) and to the less extent, Y - bearing program (delivery is made according to special request). Additional protection provided by metal-sheet cap is also available (designation 2PC).

Fig. 8 Sealing 2PB Dual sealing, combination 2P and stronger protection steel. Friction and speeds are the same as 2P, but considerably better protection against rough dirt. This type of sealing is applied in agricultural machinery. Protection steel protects from soil, dust, rough dirt and mechanical impact on the seal. Five lip seal performs contact sealing that prevents penetration of finer dirt, water, damp etc. Suitable for difficult working conditions with aggressive presence of foreign matter. Used with Y bearing units according to special request.

Fig. 9 Sealing TDT Additional metal cover with thickness of 1 mm provides reliable mechanical protection. Unique combination of six-lip sealing, double 3 lip sealing protects bearing from the outer side, one 3 lip sealing protects bearing from inner side. This presents today the best sealing system for application in agricultural machinery.